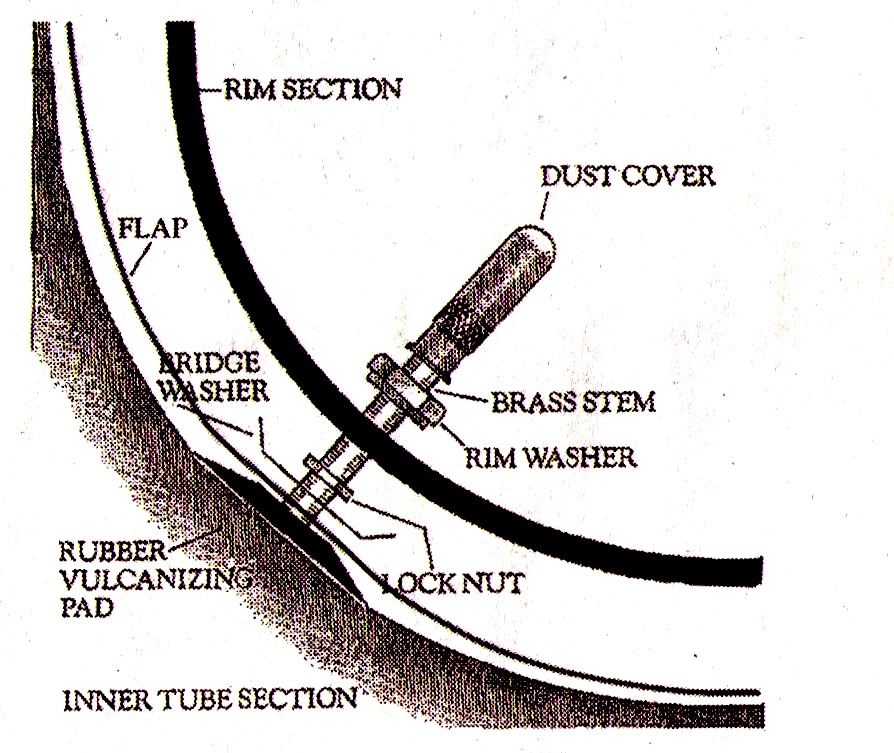

Many millions of valve

stems

were made, so they can often be found at swap meets.

Some of these were

priced at $2. Others were $3.

Sometimes you find a

stem

with

the remains of an old tube still attached.