Sorry, folks. I didn't take any pictures, so you'll just have to imagine it. Today's work was a bit of historic restoration. The wood lot where I get my firewood was once open pasture. After my uncle Charles Miller died in 1960 and the dairy operation ended, the pasture was gradually taken over by trees. Twenty years ago much of it was still in grass, especially the northeast part. But in recent years even that has been invaded, and that northeast open area has a lot of young trees in it. I want to keep some of it in grass, at least an acre or two, so today I got started on that. I began with the old buffalo wallow. It's a bison habit to roll in dust to drive off biting flies. Over years of this rolling in a particular dusty spot, a hole is wallowed out. This pasture has never been plowed, and the wallow from before pioneer days is still there. In recent years the trees have been encroaching there too, so that's where I spent my day with the chain saw, clippers, and Tordon. I got the wallow and some of the area east of it nearly cleared, with just a few more stumps to cut off and some downed trees to cut up. I started a new brush pile near the fence, and on some calm day next fall or winter it will burn.

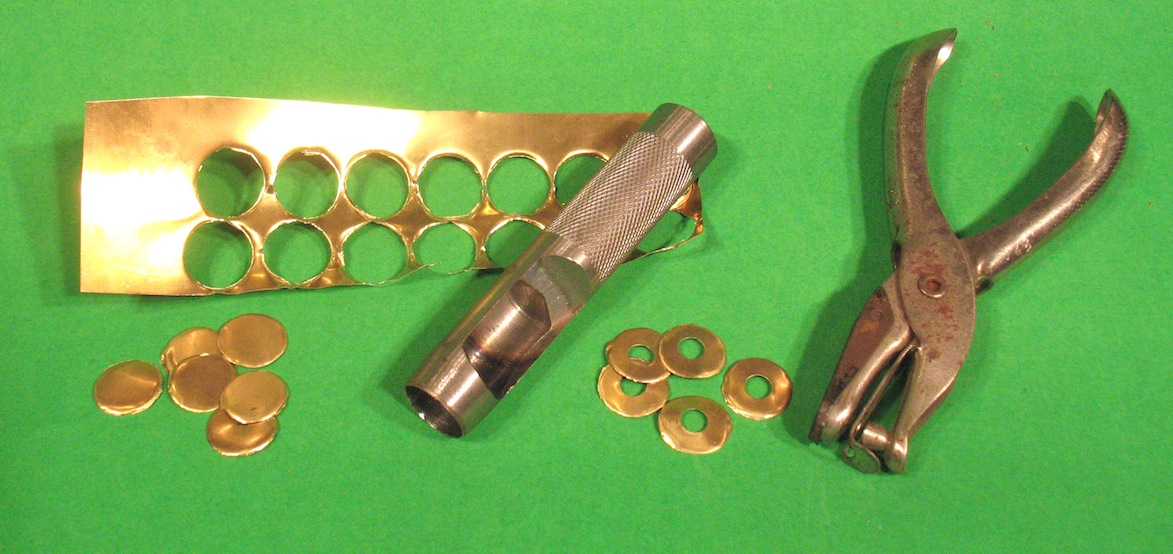

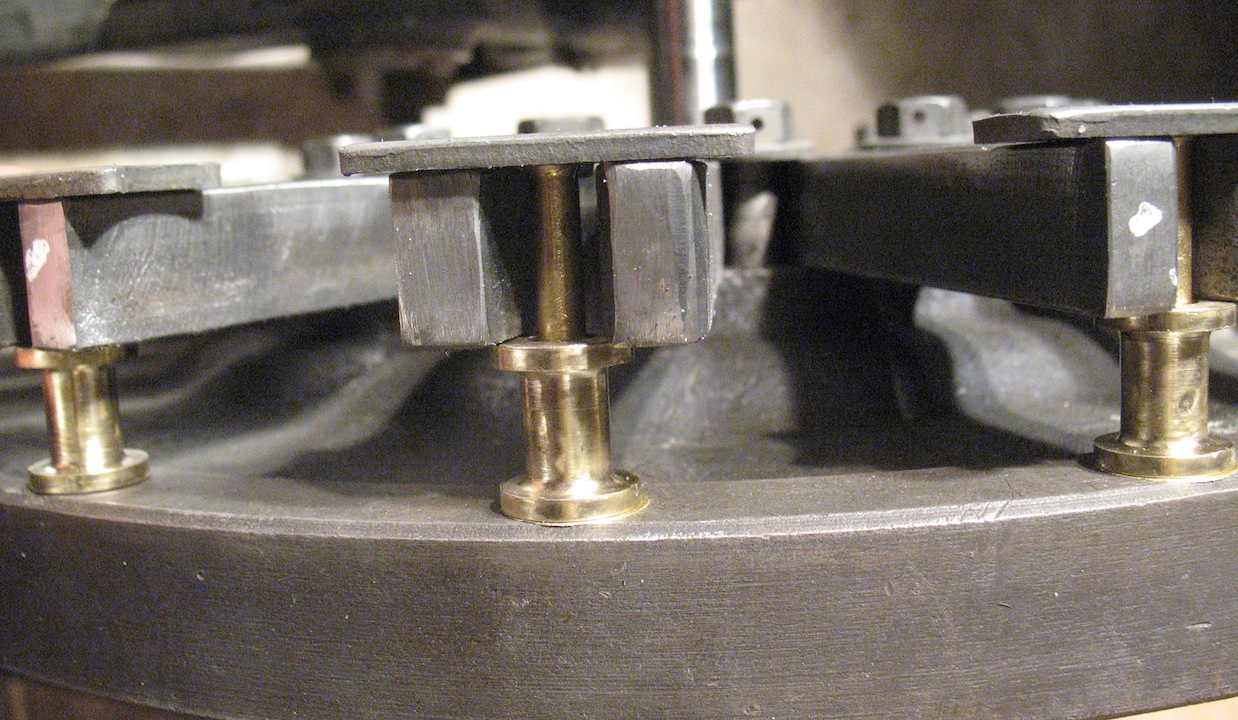

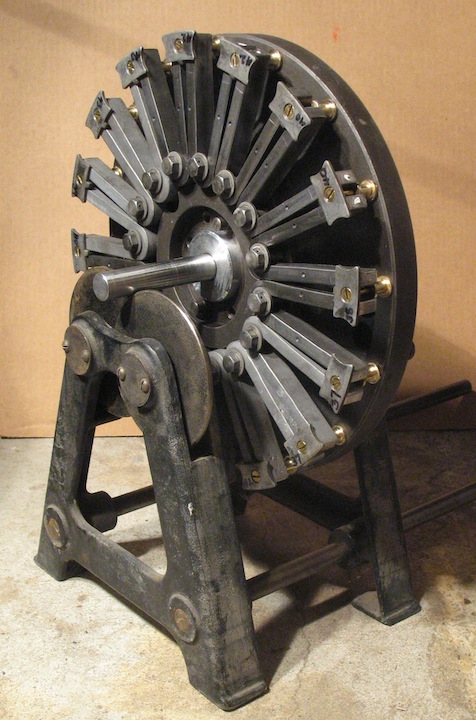

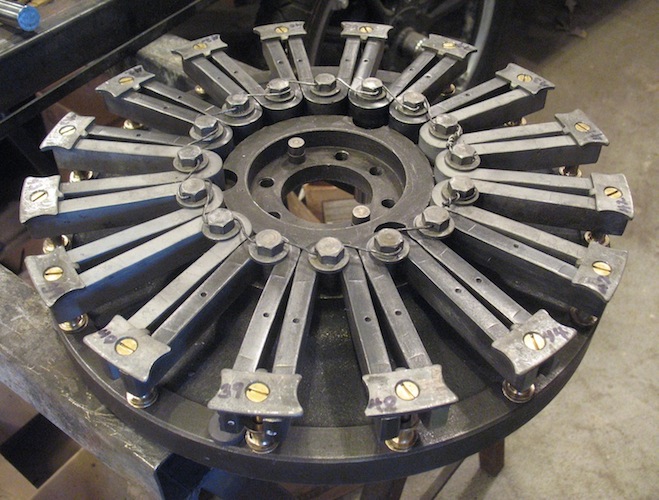

Tuesday, February 2, 2016 A nice rainfall during the night left the outside sopping wet, and I spent the day in the shop working on my magneto. One important part of magneto assembly is adjusting the height of the magnets. There are sixteen magnets, and all thirty-two poles should be as nearly uniform in height as possible. When I had all of them bolted and screwed on the flywheel I measured and found that they varied from 1.724" to 1.744". A difference of .020" is too much. Some people adjust the height by shortening the spacers under the higher magnets. I decided to go the other way and put shims under the lower ones. I made the shims of .005" brass. I needed two shims under the spacers for the lowest magnets, and some weren't that low and took only one. And of course some were close enough to the same height that they didn't need any. When I had all the shims installed and all the bolts and screws tight, the heights varied from 1.737" to 1.744". If I wanted to get really nit-picky I could have added one more shim in a couple of places, but a difference of only .007" is more than good enough. The next step was balancing the flywheel. One of the tools I made last week was a mandrel for flywheel balancing. I found that the balancer is mighty sensitive. The flywheel with the magnets on it weighs over fifty pounds, and a little five gram magnet stuck on the outside is enough weight to turn it. I spent a long time sticking on and taking off those little balancing magnets and never did get the thing perfectly balanced. The idea is to be able to turn the wheel to any position, and it will stay there. The thing was still slightly out of balance when I went to town to buy celery and pay bills, so balancing is a job to be continued. |

|

Shims under the spacers.

|

Flywheel with magnets on the

balancer.

|

Wednesday, February 3, 2016

Today I added shims under three more spacers, so all magnets are within .005" of the same height. Then I safety wired the bolts and put the flywheel back on the engine. Next will be balancing the transmission drums. There's no rain in the forecast for several more days, so I'll work in the shop while the wood pile behind the shop dries, then I'll finish splitting and stacking it in the garage.

Thursday, February 4, 2016

I spent the morning scanning more slides. This shot from downtown Los Angeles in 1955 was one of them. In the afternoon I peened the magnet screws so they won't come out of the flywheel, then experimented with trying to put solder on a transmission drum to balance it. That would be a good thing if it worked, but the solder didn't want to stick to the cast iron drum. I'll have to try something else.

Friday, February 5, 2016

I was on the road about 6:30, off to the Sunflower Swap Meet in Wichita. It was mighty slim pickin's this time. I was in the meet about 8:30 and on my way home only three hours later. The only Model T items I bought were two sparkplug/headbolt wrenches for $1 each. I did stock up on sanding and grinding supplies, and bought some 3/8" socket extensions and a couple of Phillips bits, and some Vise Grips for $1.50. There was very little Model T stuff this time, and none that I needed.

Saturday, February 6, 2016

The mess reached critical mass, and I spent the day cleaning up and organizing in the shop. I had gone from knowing I had an exhaust nut wrench to wondering if I had dreamed it, but the cleanup proved it was there all along. On the other hand, since cleaning up I have no idea where I left my BFH (Big Fat Hammer). Luckily, I have another one and remembered where it was. I had a break of an hour or so when a couple of Model T guys who had been to the swap meet yesterday stopped for a visit on their way home to Arkansas. I enjoyed the visit and got some good information from Mike the 1915 expert.

Sunday, February 7, 2016

After my customary Sunday morning playing online, I enjoyed a beautiful day outdoors with the chain saw and the clippers, clearing more trees and brush from the pasture. When I called it quits about four, I had my annual truck-stuck-in-the-mud adventure. That doesn't usually happen until March, so it's a little early this year. The forecast calls for several dry days, so I'm hoping the ground will dry out enough for me to get it unstuck sometime during the next week.

Monday, February 8, 2016

Time out. I ran out of clean sox, so today was laundry day. That used up the morning and part of the afternoon. It was a sunny day with humidity down to 35% and winds up to 35 mph, so about four in the afternoon I took a walk to the wood lot to check out my stuck truck situation. Near the truck was a puddle that had a couple of inches of water in it yesterday. Today nearly all the water was gone. I'll wait a couple more days for the ground to dry some more, then I'll try driving the truck. If it stays stuck, I'll jack the rear end off the ground and lay some cedar branches under the wheels.

Tuesday, February 9, 2016

On a chilly day that never warmed above the forties, I spent a lot of time online buying shop supplies. It pays to compare a lot of sources, as prices for some things vary widely. I also cleaned and sharpened the chain saw. Tomorrow is supposed to warm up above 60º, so I plan to get the truck unstuck and do some wood cutting and splitting.

Wednesday, February 10, 2016

I gambled and lost. A couple of weeks ago at an auction I paid 75¢ for a battery charger. It was cheap because it had mouse-chewed wires. I bought new wires and installed them this morning, but when I tried the charger it didn't work. When I have time I'll check the inside again and see if any connections came loose. My next project was changing a radiator. I want to overhaul the engine from my 1923 touring car, but that won't happen until summer. So I might as well use it until then. Today I removed the old radiator and installed the new one I bought over a year ago. By the time I finished that, much of the afternoon was gone. But I did have time to take a hi-lift jack to the wood lot and retrieve my stuck truck. The ground was still too slick to get any traction, so I jacked the rear wheels off the ground and put a lot of cedar branches under them. That did the trick, and now the truck sits behind the shop waiting for me to split more wood and haul it to the garage.

Thursday, February 11, 2016 A little bit of shop work, some computer time, then a day outside. The shop work was painting a headlight adjusting screw for the touring car. It will bake overnight and I'll install it tomorrow. The computer time was the usual deleting of spam and checking the online forums and classified ads to see if anything I need or want is for sale. The outside work was splitting the pile of wood behind the shop and stacking it in the garage. A lot of the wood was knotty and a lot of it was rotten, so it broke into small chunks no good for stacking. That made a considerable pile which will go into boxes. I may not get it all boxed up in one day, but I hope I can get it done before the next rain. I have more than enough wood put away now to last the rest of this winter and spring and get a good start next fall. |

|

|

Friday, February 12, 2016

Today's main project was boxing up bark and wood chunks that were piled up under the splitter. I filled a dozen boxes, and it looks like there's enough left to fill another dozen. All that will provide evening heat in the kitchen and the living room for at least a couple of weeks, and maybe more.

Saturday, February 13, 2016

I kept boxing bark and wood scraps until I ran out of boxes, and ended up with 23. Obviously that will last more than a couple of weeks. It looks like there's enough left to fill two or three more boxes. I expect during the next week I'll burn enough to empty that many, and refill them. In the afternoon I drove up to Wichita to see Room, because we don't get pictures like that down here in Podunk. It was well worth the trip. It's one of the best movies I've seen in the last couple of years.

Sunday, February 14, 2016

Tailoring is not one of my talents, so I'm taking my time sewing a Universal Car patch on a shop coat. I spent about a half hour stitching it today, and that was enough. I'll do a little each day until it's done. The main project of the day was web mastering. I finished a web page that I started a couple of weeks ago. I've noticed that many times folks trying to sell a car online do a very poor job of it, so I made this page to help them out.

Monday, February 15, 2016

A little of this, a lot more of that. I spent about a half hour sewing a few more inches of that shop coat patch, then took the chain saw and the clippers to clear more pasture. In three and a half hours I made good progress until the chain jumped off the bar and I had to quit. I'll need to grind a few nicks off the chain to make it fit back on the bar.

Tuesday, February 16, 2016

|

|

Wednesday, February 17, 2016

Well, that's not nice. I thought I would finish up the little piece of pasture I've been clearing, which would be trimming off and stacking branches from the trees I've cut down, cutting up and stacking the biggest trunks, and cutting off the stumps. All was for naught. My chain saw quit getting oil to the chain and the bar got so hot it was smoking. I called Husqvarna customer support and learned that getting to the pump requires removing the clutch, and that requires a special tool. Of course the local dealer no longer does repairs, so I'm going to have to take the thing all the way to Haysville. I guess that will be my first job tomorrow.

Thursday, February 18, 2016

This morning I did a few more inches of sewing on my shop coat patch, then I went and gassed up the car and took my sick chainsaw to the repair shop in Haysville. While I was up that way I went on to The Yard Store in Wichita to see what they had for canvas tarps. I was surprised to find they absolutely none. They suggested Tractor Supply Company. So when I got home I checked the TSC website. The prices there gave me sticker shock, so I checked the Orscheln website. Their prices were much better, so I'll see if the local Orscheln store has or can get the tarp I want.

Friday, February 19, 2016

That was a nice surprise. I was off to a slow start, having done my morning three miles, had a shower, breakfast, and checked email and the usual online forums. About ten I received a call informing me that the chainsaw I took to Haysville for repair yesterday was fixed. So I spent a big chunk of the day driving to Haysville and back. In the afternoon I ended the day putting that saw to use. The road in the woodlot has a Y where I have to stop the truck and back up to make the turn. So I took the saw and the clippers and started clearing live and dead vegetation to fix the Y so I won't have to stop and back up. The only disagreeable part of the job is handling wild roses. I have nothing against them unless they're in a place where they keep grabbing me when I go by. Such was the case with these, so they must go.

|

Saturday,

February 20, 2016 After checking two auctions in Winfield and finding absolutely nothing to keep me there, I took advantage of the warm day for some outdoor work. I cleared a shortcut between the branches of that Y in my woodlot road. Saturday is my eat-in-town evening, so I enjoyed a delicious repast at La Fiesta, then took in a movie. Risen is a well-made film based on the New Testament. It features good writing, with nice character development, convincing performances by the actors, and is well shot and directed. The previews shown with it were for a bombastic biblical epic and a religious-political polemic I will absolutely avoid. |

|

Sunday, February 21, 2016

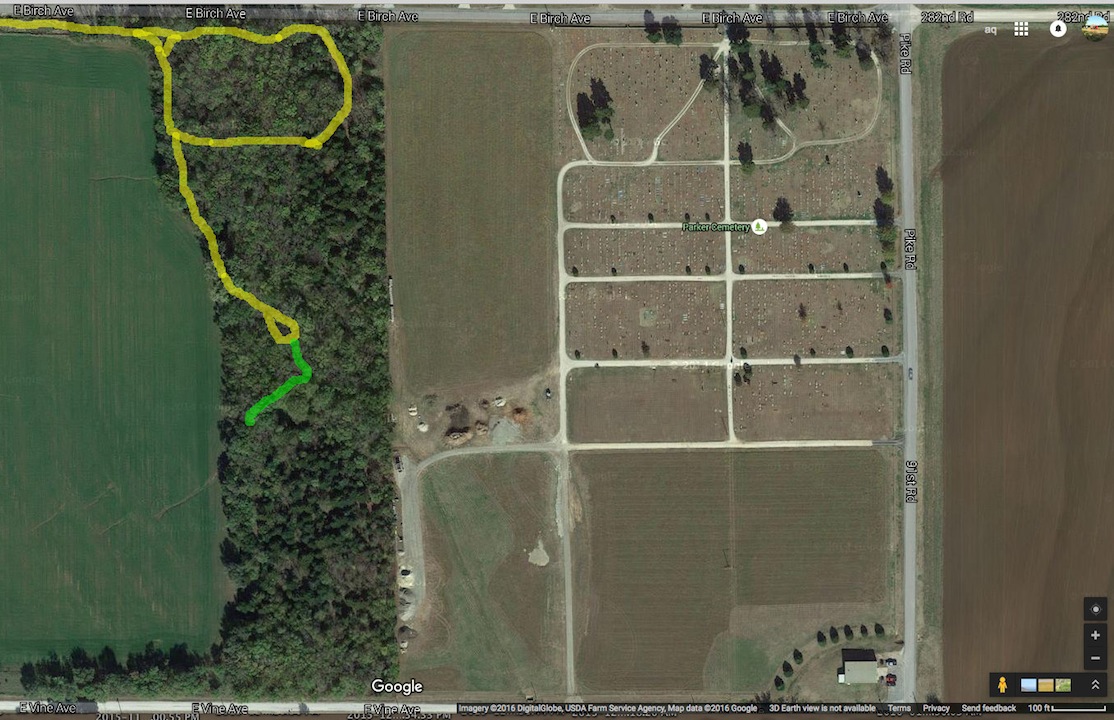

Taking advantage of one more unusually warm day in the sixties, today I worked on the new south road I started three weeks ago in the wood lot. I want to make it one large loop going down the west side, across the south end of the place, and back up the east side. I doubt that I'll finish the whole thing this year, but maybe I can do the west part and make a turnaround at the south end. Today's work was cutting off branches that were in the way, some of them fairly large. The pieces will be part of next year's firewood. This new satellite view shows the established road in yellow and the new extension I've cleared so far in green. The weather.com forecast shows cooler weather during the coming week, so I'll get back to indoor projects. I want to have at least one Model T ready to go when warm weather returns. |

|

Monday, February 22, 2016

Today's main project was balancing a transmission drum. I've never used this method, so I did a junk drum for practice. It was surprisingly easy, and worked out very well, so next I'll do a good drum to use in the car.

Boiled in lye for an hour to

remove any possible residual oil.

|

Fluxed and melted on body solder.

|

Ground away excess solder to

balance.

|

Drum balanced.

|

Tuesday, February 23, 2016

After practicing on a junk drum yesterday, today I balanced the reverse drum that's going in my car. Here's the video.

Wednesday, February 24, 2016

Today I started to reassemble my transmission. I found .012" runout on the transmission shaft, so I had to stop and research what to do about that. I got some suggestions on the Model T forum, so I'll see if any of them work.

Thursday, February 25, 2016

It was Odds & Ends day. I did some more study on transmission repair procedures. Did some vacuuming in the shop. Put some things away. Figured out a place to store the static balancer and mandrels. Fixed a drop light that had quit working because of a broken wire. Removed the transmission shaft from the engine so I can work on it tomorrow. Scanned the roll of film I got developed this week. The film had sat unused several years and was way out of date before I started using it a year and a half ago, so I had to do a lot of color correcting on the pictures. Here are a couple of them.

Taking down a scaffold, October

2014.

|

Clearing pasture, last week.

|

Friday, February 26, 2016

|

|

|

|

Saturday, February 27, 2016

Checked out an auction in Winfield and found nothing to keep me there, so I came home and spent most of the day working on my transmission, installing clutch disks and trying to adjust for the least possible runout at the fourth main bearing. I got it down to .004", and I think that will be good enough.

Sunday, February 28, 2016

Perfect weather made outside work irresistable. I cleared more of my new road, trimming off branches, cutting down a few small trees, and hauling the trimmings to the brush pile. The forecast is for more of the same tomorrow, so I think I'll spend one more day on the road before I get back in the shop.

Monday, February 29, 2016

Working on my new road, I've had to back the truck into the last 150 feet because there was no place at the end to turn around. So today I cleared a turning-around space to use until I come to another spot where it will be easy to make another one. Looking at what I have yet to do, I've reevaluated how long it will take me to extend this road to the south end of the place with a loop at the south end. I should have it done sometime this spring.

HOME

BLOG LIST

JANUARY 2016

MARCH 2016