|

These are the

plugs Ford supplied on the Model T for most of its

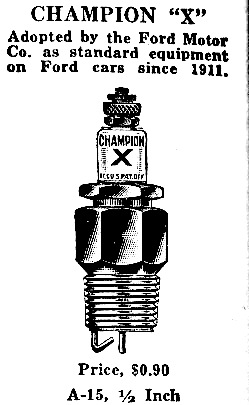

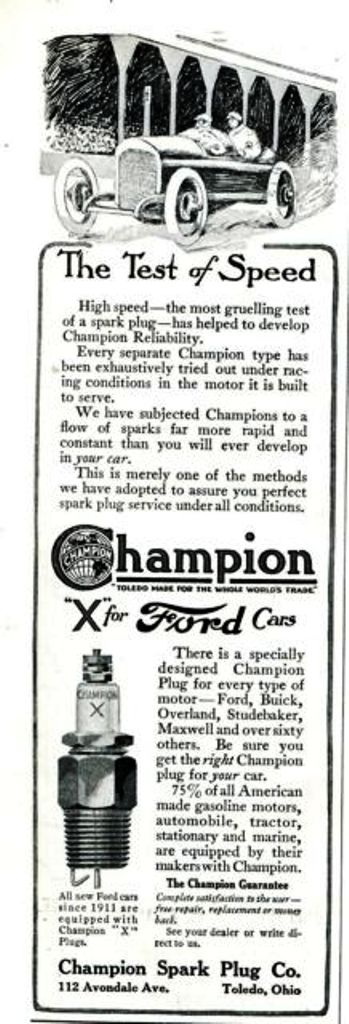

run. Early records are scarce, but Ford was using

the Champion X by 1911, along with a few other

brands, and continued using them through the end of

Model T production in 1927. Today you can still buy

new Champion X plugs, but many people run the

originals in their cars. Millions of them were made,

so there are still a lot of good ones that work like

new.

Like the Model T itself, the Champion X plug changed over the years. They're not all the same. Some folks are very meticulous in making everything on their cars "correct" for the year. If it's in good condition, any Champion X plug made in the past hundred years or so should work in any Model T. But if you're going for all the correct parts on your T you'll want to find plugs appropriate to the year of the vehicle. It took Ford about six years to produce the first million Model T's. The second million took about a year and a half. By 1921 they were making a million Fords a year, and in 1923 produced two million. The greatest volume of Model T production being in the twenties, it follows that today plugs from the twenties are most common and the earlier versions are harder to come by. But the production of over three million Fords during the teens means there were twelve million plugs on the cars, not counting the millions more sold as replacements. So even the earlier Champion X plugs can be found with patience and vigilance. |

|

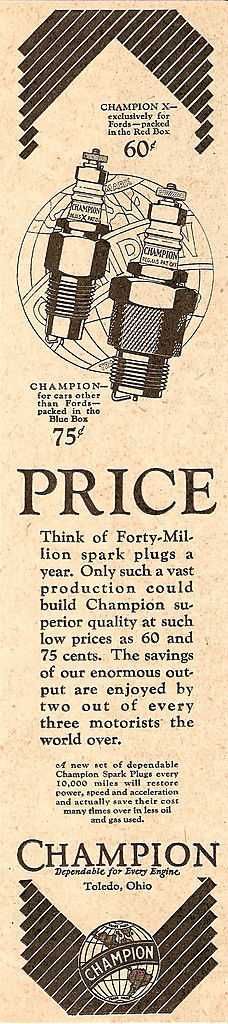

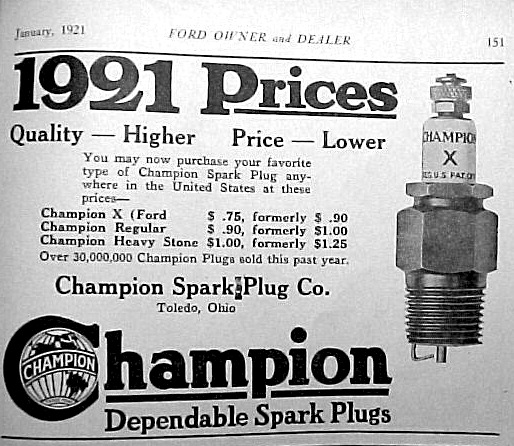

So what are the differences among the various versions of the Champion X plug? There is precious little information on exactly when changes were made, but advertising of the period can give a hint to some of them.

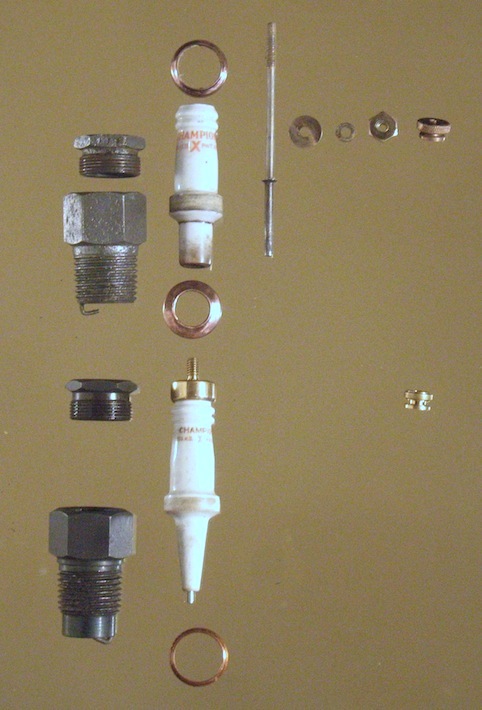

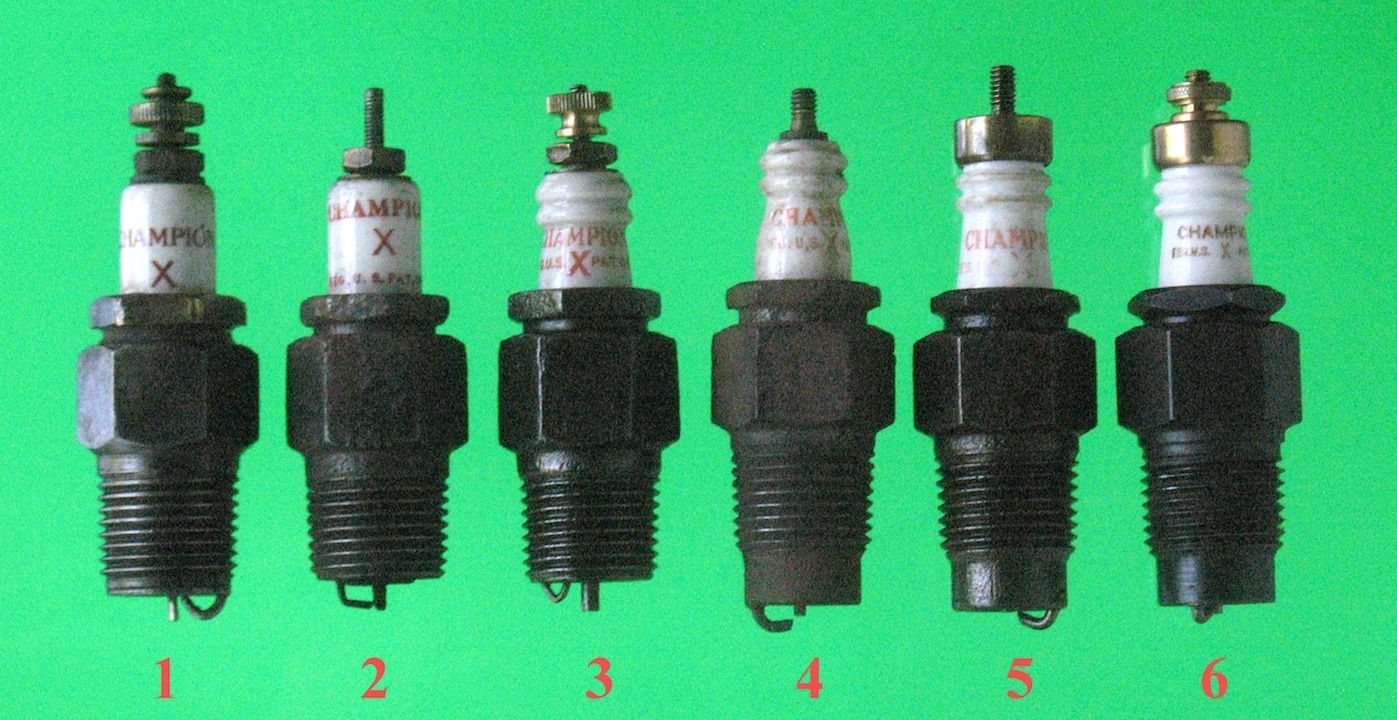

All X plugs fall into two basic groups – the early plugs made in the teens and early twenties (left), which can be completely taken apart, and the later "brass hat" ones that can't. |

At

the top here is a plug from the early twenties

completely disassembled. It has ten parts that

include copper washers that go above and below the

flange on the porcelain insulator. These washers

originally had asbestos padding in them to provide a

seal and cushion the porcelain. The bottom plug is

one of the current ones being made today. The center

post is attached to the crimped-on brass cap and

can't be removed from the porcelain insulator. There

is one narrow copper ring that goes under the

porcelain.

|

Taking

a

closer look at the tops of the two types of plugs,

we can clearly see that the center post of the

earlier version, held in with a flat washer, lock

washer, and nut, is a smaller thread size than that

on the later plug with its crimped-on cap. The

thread size on the earlier plug is 5-40, and that on

the later one is 8-32. Thumb nuts in that 5-40 size

are available from:

RV Anderson Antique Auto Engineering 3515 Route 62 Kennedy, NY 14747 Phone: (716) 267-3526 <rvmodelt@netsync.net>  |

There are several stages of Champion X evolution. The first shown here is from the early teens. The only printing on the porcelain is CHAMPION X. #2 is from later in the teens. CHAMPION is printed higher and REG. U. S. PAT. OFF. has been added below the X. #3 is from the early twenties. The porcelain has a bit of a taper and two ribs have been added at the top. This is just a guess based on the advertising, but I believe it's around 1923 when the big change comes (#4). The base of the plug is longer to accomodate the Ford's "new" higher head introduced in 1917. Why is there a six year gap between the coming of the high head and the change to a longer plug base? I have no clue. The other big change at this point is that the plug can no longer be taken completely apart. The center post now has the 8-32 thread and is crimped in. This version is pretty uncommon, and I suspect it wasn't around long. #5 is the "brass hat" version of the plug that came along in the mid-twenties and has been around ever since. It is by far the most common Champion X plug. Finally, #6 is the modern version sold today, easily recognized by the small printing.

Here's a set of

plugs from the teens, ready to use. The steel bases

and collars have been treated with gun bluing.

|

A set of

brass hat plugs from the mid-twenties and later, also

treated with gun bluing.

|

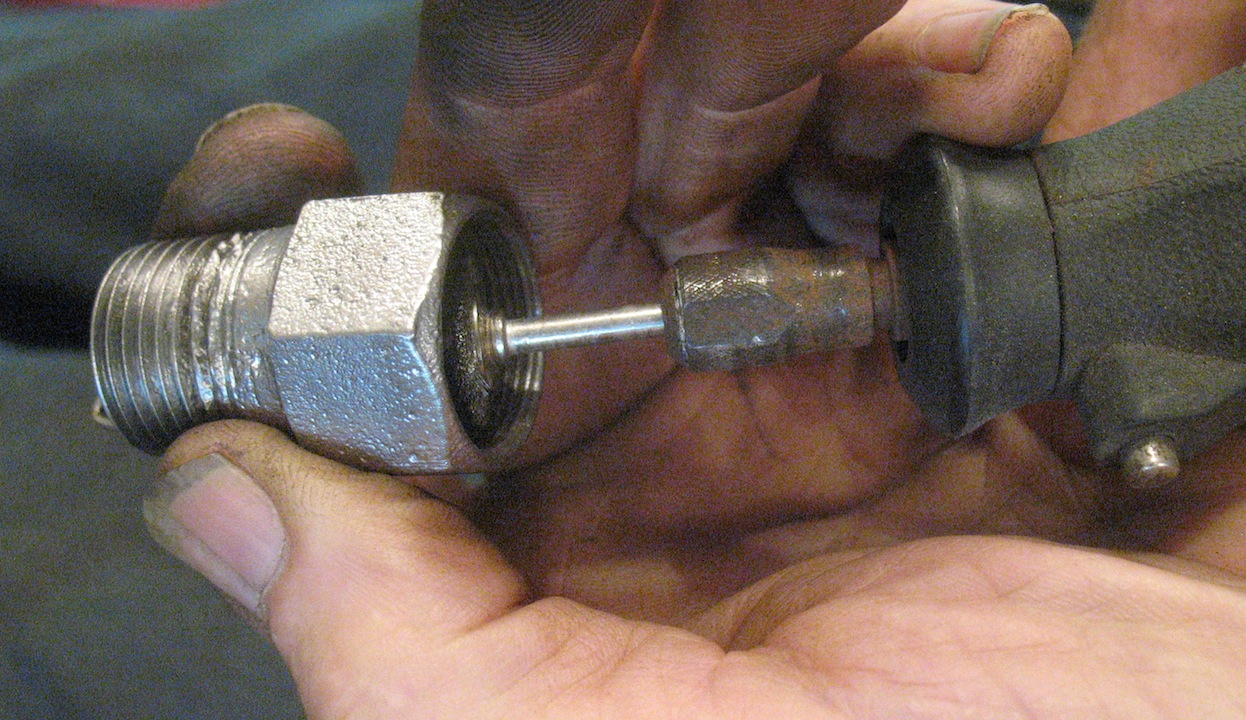

Using

a small wire brush to clean inside threads.

|

A

box of bases and collars shows that long bases are

much more plentiful than short ones.

|

Here's an unusual early plug. The base is steel, but the collar is brass. |

Apparently I got the collar too tight on this plug, and it cracked the porcelain. That sent me on a search for better gaskets. |

The search led me to

these copper crush gaskets. They have a squashable

asbestos substitute inside. With an OD of 3/4" and

an ID of 1/2", one of them will fit under the

porcelain on a brass hat plug, but it won't fit

over the cap to be used on top. On the earlier

take-apart plugs with ridges on the porcelain, you

can use one washer on top of the insulator and one

beneath to provide plenty of cushion. The

straight-sided insulators are like the brass cap

ones, too wide for these to fit over the top. On

those plugs you can only use these underneath the

insulator. I got them from http://www.gen-aircraft-hardware.com/. The part number is MS

35769-9. https://www.gen-aircraft-hardware.com/store.asp?alternate=MS35769%2D9

|

A little about shopping for Champion X plugs:

You can buy the new ones from the Model T parts dealers for $25 to $30 each. You can get them from Rock auto parts for about $25. Good originals often turn up on eBay for considerably less. The same goes for swap meets. If you're patient and keep your eyes open, you can build a full set without spending a fortune. I usd to pay as much as $10 each for any good Champion X, but in recent years I've set a limit of $7 for very nice common ones. I might go as high as $10 for especially nice ones from the mid teens. Often they can be had for less.

HOME

VEHICLE INDEX