Another day in the shop found me continuing the cleaning-up and organizing. With time out for a trip to town for shopping, I did that most of the day. I've been getting firewood from the west hedge lately, but this afternoon I took a walk down to the woodlot and found some wood I sawed a few weeks ago and forgot about. I hauled it up to the splitter and ended up with enough pieces to last three or four evenings. For the last few years I've been doing my wood harvesting during the winter, often barely keeping ahead of using it. I hope to make this the year I get alot of it cut during the spring and summer, so when next winter comes I only have to split it and burn it.

Friday, January 4, 2013

The main job of the day was house cleaning. Bringing in wood during the winter makes a bit of a mess on the floor, and letting papers pile up on my desk makes a bit of a mess there, too. While I was at it, I took down the screens in the living room, kitchen, and bathroom, and put up the storm windows. I should have done that a couple of months ago, but I guess it's better late than never. We still have 75 more days of winter.

Saturday, January 5, 2012

I was up before daylight and a little after seven I was off to the laundry. With the washing done I had a little fun shooting a picture of ten different Model T parts and posting it on the MTFCA forum as a parts ID quiz. Within a few minutes a young man who I believe is about eighteen had identified every item. He knows his stuff. This afternoon the outdoor temperature climbed into the high forties, so I took advantage of the warm weather for an outside job. I ran an extension cord out to the front porch, hooked up my electric saw, and spent over an hour turning some of the scrap lumber in front of the house into firewood. This being Saturday, I followed my custom of eating in town. In this case that meant enchiladas supremas at La Fiesta. Good eats. After decades with no decent Mexican food here, I really enjoy having a place like La Fiesta, where they do it right. After dinner I went and saw Django Unchained. With a Tarantino film I knew what I was getting, and it was fun. Plenty of ridiculous anachronisms, but very entertaining.

Sunday, January 6, 2013

After a rare night of not having to get out of bed once (old guys will know what I mean), I spent a lazy Sunday morning in the shop putting away small parts. I would put several grease cups, for example, in a plastic bag, add a slip of paper with the part number on it, and file it in the appropriate drawer. Little by little, I'm making some order amidst the chaos. The afternoon warmed up into the forties, and I went out to the west hedge to gather wood. Hedge tree (Osage Orange) is good firewood, but it's mighty hard stuff, and slow to cut. I spent about an hour cutting and splitting enough to last a couple of evenings. Then, after a layoff of three weeks, I went out for a three-mile run. Three weeks ago my time was 31:27, and I was surprised that today it was 31:52. After that much time with no running I was afraid it would be a lot worse.

Monday, January 7, 2013

Nothing big done today, just a bunch of little piddling odds and ends. They included cleaning a rat's nest of leaves and twigs out of a box of antique spark plugs, going to town to buy some lumber for the front porch and a halogen bulb for a shop light, posting some pictures on Facebook and some comments on the Model T forum, putting another coat of paint on the lantern I painted last week, and more organizing in the shop. Maybe tomorrow I'll get some more firewood cut and split.

Tuesday, January 8, 2013

Today's main project was research. I'm checking Model T carburetors and parts to see what taps and other tools I'll need for rebuilding them. One tap was easy to figure out, but buying it took stops at five different stores. This is because of one of my pet peeves. Too many taps and dyes are unmarked or have the sizes printed on them in ink that will soon disappear. At the fifth store I finally found one with the numbers stamped into the metal. In the afternoon I took an hour for firewood, cutting up a dead tree in the woodlot that's been waiting for a few years. I cut a couple of days' wood from it today, and there's more to cut. I think I may get a week's worth of wood out of it.

Wednesday, January 9, 2013

Morning was for more carburetor research, figuring out thread sizes and looking online for taps. Afternoon was for grocery shopping and exercise. My three miles took 31:05, which is not bad considering how much running I haven't done lately because I'm a cold weather sissy.

Thursday, January 10, 2013

Today's main project ate up most of the day. I was dismantling a Holley G carburetor and taking measurements for parts and tools I need to make for rebuilding. The first part of the job was just getting the mud dauber nests out of the bowl and digging out the mud that other bugs had packed in the passages. After that it took a long time to get various little parts out without wrecking them.

|

|

Friday, December 11, 2013

More carburetor work used up most of the day. Most of that work was measuring parts and drawing plans for tools I need to make. Some parts are best removed with special tools designed for the specific part. Monday I'll be off to the machine shop at the juco with my plans to start making tools. Today's last chore was a trip to the wood lot to cut more firewood. The forecast shows a couple of chilly days coming up, so more wood is in order. Meanwhile, the countdown shows 68 days to spring.

Saturday, January 12, 2013

It's time I made some progress on one of my major projects, so today I got back to the roadster that's been sitting for months with the head off. I was going to install new rings, but got sidetracked with a lot of other things. I've never been able to start the car on magneto, so rather than just install new rings I'm going to pull the engine and transmission, check everything out, replace transmission bands if necessary, and charge the magnets. Today I cleaned up in the shop, vacuuming under and around the car, and did a lot of the little chores that have to be done before pulling the engine: removing the radiator and support rod, moving the steering column out of the way, etc., etc. This evening I went to see Gangster Squad. It's a very well done shoot-em-up, with good performances and a wonderful depiction of Los Angeles in 1949. The reviews ranged from enthusiastic to very negative, but I side with the enthusiastic folks.

Sunday, January 13, 2013

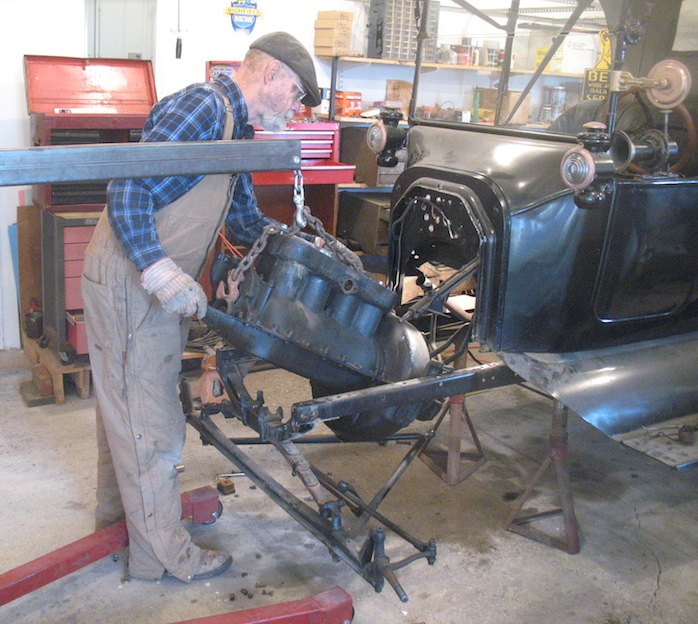

I lazed in the sack until after eight, then spent the morning in the workshop doing more organizing and cleaning up. I spent the afternoon at the Patterson auction in Oxford. As usual, there were a few good items I didn't get because others were willing to pay too much, but I did score a few bargains. There was so much stuff to sell that when the outdoors warmed up as much as it was going to, somewhere in the low twenties, Ken went outside and sold what was out there while Rick kept selling inside. Sometimes at a two-ring auction like that you miss something, but I don't think I did today. After chow this evening I went back out to the shop and worked on the roadster. I removed all the bolts holding the body to the frame so I can raise the body to get the engine out. Tomorrow I'll lift the body and get some blocks under it, and if I have time maybe I'll even finish pulling the engine.

|

|

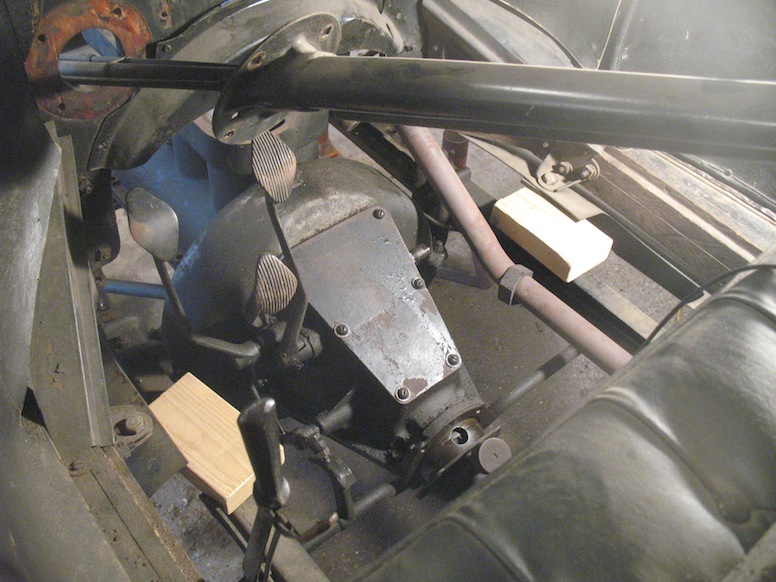

| Monday, January 14, 2013 Well, I never went off the place today. So I didn't get to the machine shop to start making my carburetor tools. Instead I spent the day working on the roadster. The first part of the job, which took most of the morning, was making a body lifter. To get the engine out of the early Model T's, the body has to be raised off the frame a couple of inches. So I made a tool that hooks under the fireweall to raise it. With that tool finished, the next job was raising the body. That was quick work, and it was simple to insert a pair of 2x4 blocks over the brackets to hold the body off the frame. Then came removing nuts and bolts holding the engine in place and dropping the wishbone out of the way. The nuts and bolts are a bit hard to reach, so that part went pretty slowly. The last part, raising the front of the engine to lower the pedals and then sliding the engine forward until the pedals cleared the firewall, was a pretty easy affair. When I put the engine on the stand, I found that I'll need to alter the stand a bit to support the center of gravity of the combined engine and transmission. I'll get started on that tomorrow. |

|

|

|

|

|

Tuesday, January 15, 2013

For the second day in a row, I never went off the place. I spent the morning changing the adapter on my engine stand to put the pivot nearer to the center of gravity so the transmission end of the thing isn't so bottom heavy. In the afternoon I went through a lot of stuff on the bottom east shelf, cleaning up, sorting, and putting away. Most of it was auction purchases that I brought home, laid on the shelf, and left there until today. Lots of drill bits, reamers, and taps. Some of it was sticking out from the shelf, blocking the way for my engine stand, so today was the day to deal with it. Wally dropped in and we chewed the fat for an hour or so, then I finished up the cleaning and rolled the stand with the engine on it over by my work table. Tomorrow I'll start digging into the engine to find out what work it needs.

Wednesday, January 16, 2013

Wednesday, January 16, 2013Good grief! It's only the middle of January and already daffodils are poking up. They're always first, but this is ridiculous. We still have another nine weeks of winter. The weather's mild right now, but those plants are in for a rude surprise sometime in the next few weeks. Meanwhile, I got in some more shop time. I started taking parts off that transmisson out of the roadster. I'll be checking everything for wear and fixing or replacing anything that needs it, and recharging the magnets. A 1915 Ford should be able to start without a battery, but I've been using one because the magneto didn't put out enough juice to get the car started. As usual, everything takes longer than you think it will. I got the cover off and some small parts cleaned, and that was it. Most of the afternoon was for errands like renewing the registration on my trailer and grocery shopping.

Thursday, January 17, 2013

Morning: more engine work. Afternoon: cut firewood. Thats it.

Friday, January 18, 2013

The morning found me back in the shop working on my roadster engine/transmission. The specific chore was reconditioning nuts and bolts, cleaning out plugged cotter pin holes and chasing threads with taps and dyes. It's slow work, but needs to be done. The adventure of the afternoon was a drive down to Ponca City for shopping. The main object was getting a new TV to replace my aged set, which appears to be dying. While I was at it I bought some marked-down flannel shirts for next winter, and some Round House overalls. I have to get those in Okieland because they aren't sold here. My last Ponca stop was to buy a hundred feet of 12 gauge wire. I'm going to make an electromagnet for charging Model T magnetos.

Saturday, January 19, 2013

This was laundry day. While the clothes washed I went to the welding supply and bought some one inch round iron for the core of my magnet charger. After doing laundry I went to an auction on the east side of Winfield. It was remarkable for the abundance of stuff you'd have to pay me very well to haul away. There were a few minor items of mild interest, but definitely not worth waiting for the auctioneers to sell all the junk before getting to them. I came home and did other things. One was drilling cotter pin holes in some bolts. Another, which took longer, was installing the new TV. You don't just plug it in and turn it on and see pictures anymore. Now it's a major project. In this case that meant a phone call to customer support for help. Eventually I got it done, so now there are pictures.

Sunday, January 20, 2013

Nothing remarkable today. I worked in the shop on minor roadster chores, removing some front suspension and steering parts and checking what needs to be replaced, and I did some online research on parts and services. This afternoon I took my newly sharpened chain saw out in the back yard and attacked the big dead tree I've been working on. So far all I've used is a couple of big branches, with several more to go before I get to the trunk. This tree should provide enough wood for at least a couple of weeks, maybe even a month. I ended the day with my three mile run, which I did in 31:10. Not great time, but not bad either.

Monday, January 21, 2013

This was radiator day. In the morning I phoned a shop that does radiator restorations and discussed what the radiator from my 1915 runabout needs. Then I went online and did some research. Then I spent the rest of the day crating the radiator up so I can send it off to the shop. It's all packed up and ready to go tomorrow. I hope to have the car back together and ready to drive sometime this spring. That means I'll need to finish installing new rings, charge the magneto, reassemble and repaint the engine and transmission, replace front suspension and steering bushings and blast and repaint front axle parts, replace bolts in the frame with rivets and repaint that part of the frame, open the rear axle and rebuild if necessary, and put it all back together, plus a few minor odds and ends. Good luck to me getting all that done in just three or four months.

Tuesday, January 22, 2013

This morning my roofer called to tell me he's received the materials for my front porch roof, so that determined my afternoon work. The outside temperature in the morning was about 20º, so I spent the morning in the shop working on the roadster. I removed the spindles and worn spindle bolts and other front suspension parts, and cleaned them up to check for wear. I found that I'll be replacing all the front suspension bushings. About one PM I went to town and used a discount card at the hardware store to buy some paint, then shipped my radiator off to the restorer, then stopped at the market for celery. When I got home the temperature had climbed into the forties and I was ready to get busy on the roof. I started at 2:30, and by 4:30 I had removed most of the old roofing. Tomorrow I'll get the rest of it off, and replace a few bad boards, and maybe get the new trim installed around the edges. I should have it all ready when the roofers come on Friday.

Wednesday, January 23, 2013

It was a two-activity day. In the morning I went to the machine shop at the juco and made a drift to punch out a stuck Model T spindle bushing. I spent the afternoon on the porch roof. I finished taking off all the old roofing and replaced a broken board. Unfortunately I have more carpentry to do tomorrow, and the forecast is for a high of 32º. I expect I'll do the work in stages and retreat into the shop to thaw between sessions.

Thursday, January 24, 2013

The day started at 25º, which was warmer than I expected. I spent the morning in the shop working on the roadster, taking off the front spring and other suspension parts. That was slow going, as some parts were pretty firmly stuck in place. By one the outdoors had warmed up to 32º, and I spent the afternoon working on the front porch roof. I finished replacing a few bad boards, then started removing old trim around the edge and installing new. I got most of it done, but came up short of lumber and had to go to town for another six feet of 1 x 6. That will be the last piece of trim, so I should be able to get it in place before the roofers come to install the Duro-Last.

Friday, January 25, 2013

|

|

|

The ruferos arrived about nine this

morning to install the Duro-Last on the front porch roof. I split my

time between working in the shop on my roadster and watching what they

were doing, and making suggestions. The crew chief was the owner's son,

and doesn't yet have years of experience, so I wanted to keep an eye on

things and make sure the work was done the way I wanted. For a

while Daisy took a sunny spot on my bed and helped me watch. The

roofers finished about two and left, and I didn't waste any time

putting up my plastic temporary windows. I learned my lesson the last

time I did that, with the wind blowing, and this time I wanted to get

it up while the wind was calm. So now I'm ready for rain, if it ever

comes. The forecast is for a chance of rain Saturday night, and now

that the roof is ready I say bring it on. We're now in the driest

period in over fifty years, and some moisture is really needed. |

|

|

Saturday, January 26, 2013

Early this morning I was off to Hutchinson for the annual mid-winter Model T clinic. This is always a popular event that draws a good turnout. This year Verne Shirk and his daughter Kimberly talked about rebuilding the Model T rear axle. Kimberly is a senior at Wichita State, but found time to rebuild the rear end in her 1914 touring. As always, it was an informative day, and worth the trip. As usual, there was some nice model T's on display, from 1910 to 1927.  |

|

|

|

|

|

|

|

Sunday, January 27, 2013

Wichita had some actual rain, though it may not have amounted to much. But here the moisture was just enough to wet concrete surfaces. Walking across dirt stirred up dust, so if there was any precipitation it was the bare minimum to qualify for the designation. I spent the day on the roadster, dismantling and researching parts to see if they're the right ones for a 1915 car.

Monday, January 28, 2013

This would have been a great day for sand blasting, with an afternoon high over 70º and a nice breeze to carry away the dust, but I never got to it. I spent all day getting roadster parts ready for blasting, and researching which parts are right for 1915, and looking for replacements for the parts that are wrong. The rule that everything takes longer than you think it will is still in effect. That's OK. There will be other days good for blasting.

Tuesday, January 29, 2013

Rain! Yay! It was just starting when I got up at seven. By ten there were puddles in the yard and even the ground under the cedars was wet. It was cloudy all day, but by noon the rain was over, and by five all those puddles had disappeared into the thirsty ground. I spent most of another day in the shop dismantling roadster parts and getting them ready for sand blasting. I have a good many ready whenever a good day for blasting comes along.

Wednesday, January 30, 2013 This morning's main

activity was more work on dismantling and cleaning roadster parts,

getting them ready for sandblasting whenever the right weather comes

along. Some of the parts on the car are OK and I'll keep them, some are

worn out and need to be replaced, and some are OK but wrong for 1915,

and I'll replace many of those with the right parts. An exception is in

the front suspension. A stock 1915 Ford has the front radius rod

(wishbone) attached to the spring perches above the axle. After 1918,

the wishbone is attached below the axle, which is a more stable and

safer arrangement. Even though it's "wrong" for the year, I'm going to

keep the below-the-axle setup. During work on the front axle I

discovered a mystery. The tie rod featured some ugly welding in the

center. I assumed it had been repaired. But it turned out to be almost

two inches longer than it should be, so it had been lengthened. When I

examined the spindles I found out why.

|

On the right spindle (shown left), the hole for the arm is perpendicular to the spindle

shaft. But on the left spindle the hole is at an

angle of about 80º. I posted that picture on the Model T forum. It turned out that a couple

of other people have found similar odd spindles with the cockeyed hole,

but nobody knows what

they're for, or has found any information on them.

Today's other work included sewing a patch on a new shop coat, as the old one's getting kind of ratty, shopping for groceries, repairing my chain saw, and harvesting some wood. The saw's problem was that sometimes the chain would fall off. I took a bar from an old saw and installed it, and the saw was good as new. |

|

Thursday, January 31, 2013

Being even slower with a needle and thread than I am with other work, I thought I'd spend just an hour on my patch sewing and then go on to something else. But I decided to finish it up today and have done with it. So I finished that about noon. Next was a shopping list. I got a parts catalogue and started making up a list of new roadster parts I need to order. I'll place the order after I go to the Sunflower Swap Meet tomorrow. No need to pay shipping on something if I can buy it locally. The list used up a good chunk of the afternoon, then I went to town for shopping, bill paying, and to gas up the car for tomorrow. That was my day.

HOME

BLOG LIST

DECEMBER 2012

FEBRUARY 2013