Again, everything takes longer than you think it will. Changing a tire takes just a few minuites, right? Not today. After I removed the lug nuts I expected the wheel to just slip off the lugs as always. But it was stuck fast. No amount of pulling would move it. Tap it wit a hammer? No good. Pry it off with a long bar? Nope. Finally I put an eight foot 2x4 against it from the other side of the car and pounded it off with a heavy hammer. That few minute job stretched over an hour. What else did I do today? Unloaded yesterday's cargo of bricks. Went to town and got a new tire and installed it. I took the precaution of slathering on a bit of anti-seize compound to prevent a recurrence of the stuck-wheel adventure. Watered all the newly planted plants. Read the water meter and wrote a check to pay the bill. Put six gas cans in the truck and went to fill them and the truck. Thirty gallons should last most of mowing season. I ended the day with mowing after dinner until it got dark enough that I couldn't see what I was doing. Tomorrow: more mowing.

Saturday, May 2, 2015

Well, at least one job is finished. Today I hauled home the last load of bricks. It turned out there weren't quite as many as I thought, "only" 888. That's about 1.1¢ each. Some will be used for a little patio to keep the barbecue from sinking into the ground when it rains, some will make a pad under the back yard swing, and some will make a floor for a new tool shed. With brick fetching finished, I hauled away piles of yard waste and mowed. I really enjoy having my truck back. The ground has dried out enough that I was able to use the north brush pile without getting stuck in the mud. Today's other job was planting the American sweet gum and the red maple that came in yesterday's mail. I buy my trees from the Arbor Day Foundation because they are cheap, cheap, cheap.

|

Sunday, May 3, 2015

On a lazy Sunday morning I got off to a late start, checking email and websites. About ten I got outside and spent a half hour watering all the new plants, then got back to work on the back porch project. I replaced a stone on the east side and laid a whole row of stones over the window on the west side. I hope to be done with all the stone masonry in a few days, then I can get busy building the new roof on top of it. I'll be happy if I can have the new roof finished by the end of the month. I ended my masonry for the day about two, made a trip to town in the roadster for groceries, then did a little movie project. In reply to a request on the Model T forum, I made a short video on using the Ford screw jack. |

|

Monday, May 4, 2015

After watering all the new plants, I got back to laying stones on the back porch. I got most of the stone work done around one in the afternoon, washed my tools, and took time out for a trip to town for some information. It seems brake bleeder valves for my truck are made of unobtanium, and I'll have to make them myself. My first stop was at AC Steel to see if they could supply the 7/16" hex stock I'll need. Nope. So I went to the junior college to ask the machine shop instructor. He suggested a place in Wichita, so I'll try it the next time I'm up that way. After my visit to the juco I wrote this little story about it on the MTFCA forum.

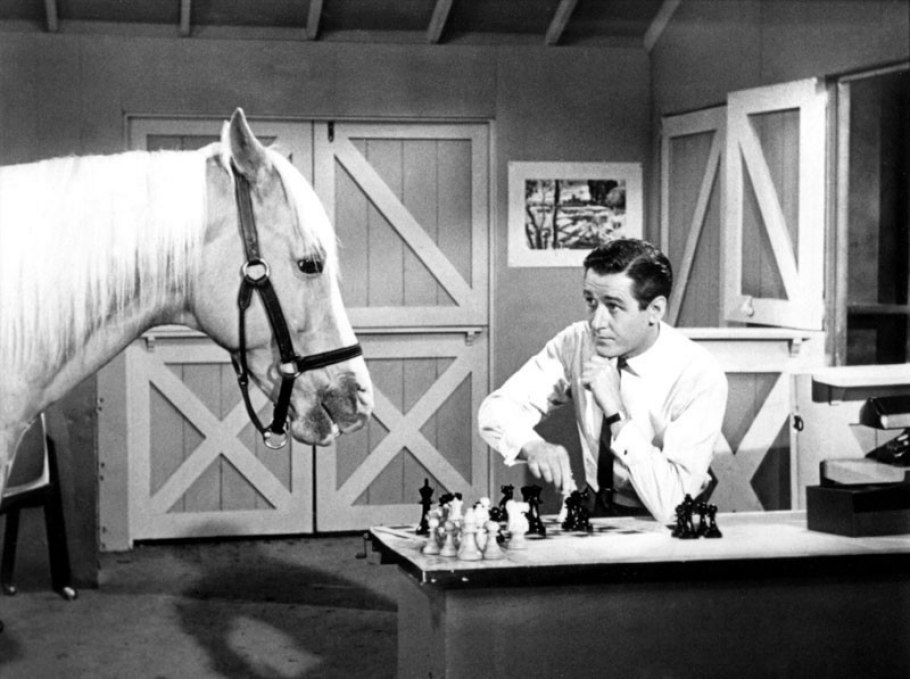

My Car, Mister Ed

Remember how he only talked to Wilbur? When anybody else was around, he wouldn't say a word.

This afternoon I stopped at the juco to ask the machine shop instructor if he knew of a local source for some hex stock. He and the boys were looking over the roadster and asking all the usual questions about it, and marveling that it will be 100 years old next month. I explained the operation, how "all black" wasn't always true, what kind of oil, and so on. When I had blathered long enough and it was time to leave, I set the spark lever down a little, did the same to the throttle, switched to MAG, and pulled. Usually when it's warmed up and I do that it starts on the first or second pull. Not today. After about a dozen tries without even a cough, I cheated and switched to BAT. Even with that, it took another half dozen pulls to get it going. After that It ran fine all the way home. When I got home and backed the car into the shop and shut it off, I set the spark and throttle down a little bit, switched to MAG, and pulled. It started right up on the first pull. Mister Ed.

When I got back from town I had some time left for a bit of work, so I got started cutting and fitting boards for the back porch. That will continue tomorrow.

Tuesday, Cinco de Mayo, 2016

After the usual morning plant watering, I got right to work on the back porch again. I spent most of the day in carpenter mode, cutting and fitting boards. I did have to take time out for a trip to town for wood stain, which I'm using to darken the new wood so it will resemble the old wood which is darkened with age. With the weather forecast predicting several wet days, I also had to take some time preparing for that. I put the mowing tractor in the barn, closed up the Suburban, and fixed a window on my truck so it would close. I put tarps over the lumber on the front porch to keep it dry in blowing rain, and got all my tools put away. I was just finishing spreading tarps over my work area a few minutes after five when the moisture arrived in the form of a light mist blowing in from the south. The forecast claims very high chances of rain for several days, so maybe there will be enough to do some good.

Applying wood stain.

|

Last carpentry of the day: nailing on a temporary board to keep things in place. |

Wednesday, May 6, 2015

An inch and .72" in the rain gauge overnight saved me having to water. It will make the plants happy, and the little frogs are singing. I took the morning to do laundry and shop. In the afternoon I took advantage of a break in the weather to make the last truss for the back porch roof. I did the sawing outside, but nailed it together and stained it in my shop. Next I'll put that in place and start cutting and nailing on the roof boards. With most of the stone work done, the rest of the porch reconstruction will go faster. I may even have it done in a couple of weeks. We shall see.

Thursday, May 7, 2015

There was only one hard thing about today's work. I finished staining the center truss for the back porch roof, then I cut roof boards, and stained them. The hard part was finding indoor space where I could do the staining. With a high chance of rain in the forecast I didn't dare try it outside. I did figure out where I could do the work, and got four of the eight boards done before I had to go to town for another can of wood stain and to buy groceries and gas up the car. I also checked the rain gauge and found 1.2". Added to what was in the gauge yesterday morning the two day total is almost three inches. The forecast shows rain chances of 90% tonight, 70% tomorrow, 100% on Saturday, and 80% on Sunday. It wouldn't surprise me if the total for these few days reaches over six inches. |

|

|

Friday, May 8, 2015

It was another back porch day, all day. The only other thing I did was finish unloading the bricks from the Suburban and drive it to town for more boards. I installed the middle truss and nailed on the top two roof boards to hold the trusses in place, cut and fitted boards for the south wall, and made shims to get things level and even. If the forecast of several dry days in the coming week is right, I may have this job done in a couple of weeks.

Saturday, May 9, 2015

A break in the weather all morning allowed me to measure, cut, and stain the boards that will go around the tops of the walls between the rafters. I had them finished and the last coat of stain on them by three, then, feeling a little drowsy, I took a nice afternoon siesta for an hour. Finally, I got to work on filing digital pictures. The last ones I did were the January photos, so I have over three months of indexing to do. That's absolutely necessary if I'm going to be able to find a particular shot when I want it. This being saturday, I went for my weekly meal in town. This time it was enchiladas rancheras at La Fiesta. As usual, it was a tasty treat. After dinner I took in a movie, Ex Machina. I would classify it as intelligent science fiction. I liked it. Smart writing, well acted and directed.

Sunday, May10, 2015

All morning I indexed photos, and by two I had February, March, April, and May up to now all finished. While I was at it I figured out a procedure to index as I go so they don't pile up on me and take so long to do a month or more at a time. About two the weather was looking good and I decided to get back to work on the porch. I had just removed the tarps when the first big drops fell. Within two minutes it was a soaking downpour. I managed to get at least one of the tarps back in place before I fled inside. Most of my tools didn't get too wet. About three it looked like it was safe to try again, so I took off the tarps and installed the boards along the tops of the walls. The forecast for tomorrow shows 0% chance of rain, so I should get a lot done.

Monday, May 11, 2015

Another day of porch rebuilding, with the only interruption a drive to town in the roadster to buy more nails. It started with me in my winter clothes for a morning in the low forties, pretty chilly for May. I spent most of the day cutting and installing boards for the wall above the door, and nailing on most of the roof boards. I left off the lower ones because I want to keep easy access to the tops of the stone walls. I intend to finish up the stone work in the morning, then I can put on the rest of the roof boards. I want to get as much done tomorrow as possible, because the forecast shows a 100% chance of rain on Wednesday, followed by 90%, 80%, and 90% through Saturday. After all the dry weather in recent years I'm not complaining at all about the moisture, but it does slow things down a bit.

Tuesday, May 12, 2015

My only venture off the place today was a trip to the lumber yard for another sack of mortar mix. I finished laying the remaining stones at the tops of the walls, wrapping that up about 1:30. The rest of the afternoon I installed the rest of the roof boards, nailing the last one in place at 4:13. The forecast calls for a return of wet weather, so I put away the tools and got the tarps in place. Tomorrow morning is supposed to still be dry before the meteorological entertainment arrives in the afternoon, so I hope to install all the shingles above the door before the rain arrives. When It's raining I'll work inside, installing the lights.

Wednesday, May 13, 2015

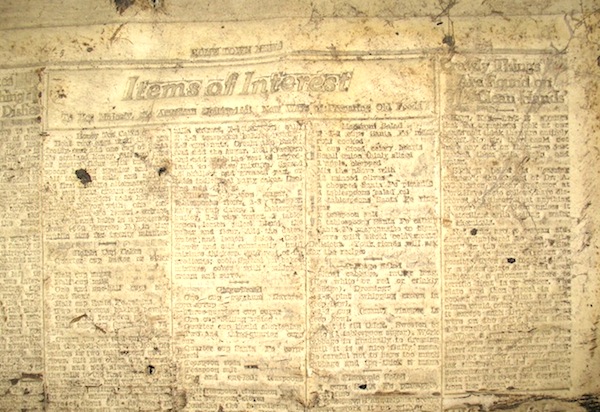

Falling weather put a stop to my outside work, but not before I got all the shingles above the back door nailed on. I was just wrapping up that job when a fine mist/sprinkle began. I quickly put my tools away and got the tarps back in place, then turned to my afternoon work. That was inside the porch, where I cleaned mortar dust off the woodwork and restained where it was needed. The rest of the time I worked on the inside light, finding some of the parts I'll need and getting some of the wiring in place, and lining the inside of the wall above the door with 1932 stereotype matrices from the Arkansas City Daily Traveler ("3¢ in town and 5¢ out of town"). Those are what my grandfather used instead of tar paper in building the house.

Thursday, May14, 2015

This morning I took a picture showing the newly completed wall above the back door, with its unique inside lining. The loose conduit shows that I still need to install the lights. My trip to town in the roadster included a visit to the saddle shop to get some leather for a tire pump, the hardware store for 14 gauge wire, the electric supply for flexible conduit, the lumber yard for roof materials, and a couple of grocery stores for food. I also had the adventure of running out of gas on Summit Street. Fortunately it happened just as I came to a filling station, so it

wasn't the problem it could have been. When I

got home the truck from the lumber yard had just driven in to deliver

the wafer board and roof edging I bought in town. When that was safely

in the garage and I had the groceries put away, I got back to work on

the porch. I cut some boards that will go along the north edge of the

roof. This evening I stained them, and they'll go on tomorrow whenever

the weather permits.

wasn't the problem it could have been. When I

got home the truck from the lumber yard had just driven in to deliver

the wafer board and roof edging I bought in town. When that was safely

in the garage and I had the groceries put away, I got back to work on

the porch. I cut some boards that will go along the north edge of the

roof. This evening I stained them, and they'll go on tomorrow whenever

the weather permits.Friday, May 15, 2015

I spent way too much of this rainy morning online, but finally got to work about ten. With the outdoors wet, I got started on installing the wiring and lights in the back porch. There used to be just an outside light, but I decided to put one inside too so I don't have to fumble with a key in the dark. With time out to go buy some flexible conduit connectors, I worked on it all day. I got the inside light in and working, and will put up the outside one tomorrow if the weather allows it. After one more wet day tomorrow, the following three days are supposed to be dry. I don't know if I can finish the whole back porch project in three days, but I should get a lot of it done.

Saturday, May 16, 2015

Starting at 7:30 this morning, with 0% chance of rain in the forecast until afternoon, I set about installing the roof boards that will hold the facia on the north side of the back porch roof. I was just finishing that about 8:30 when the first rain arrived. I put the tarps back in place and moved inside to work on the lights. With the next break from rain, I put up the outside light fixture. I was just finishing that when the next rain started. Again I moved inside, and set about finishing the wiring. About one I had the wiring done, the power back on, and both inside and outside lights working. Next came manufacturing. This electrical work will all be in plain sight for all to see, so I'm trying to keep it as original as possible. I'm reusing all the old hardware I can, but I don't have everything. You can't go to the hardware store or electric supply and buy a block-off plate to fit a 1935 junction box because they're not the same size. So I had to make my own plate. It's not exactly like an original, but it'sclose enough that nobody will notice.

Sunday, May 17, 2015

Last night's storm left over an inch and a half in the gauge. 1.65", to be more accurate. I took advantage of the first of three days predicted to have a 0% chance of rain and spent it on the back porch roof. I got all the wafer board cut and screwed on, even with an hour off for a nice afternoon siesta. Tomorrow I'll put on the edging and get started putting on the roofing. Once that's done, I think I'd better take some time for more yard work. Some of the grass is getting pretty tall and there are weeds demanding attention.

Monday, May 18, 2015

It should have been done by noon, but I nailed the last piece of trim along the north side of the roof at 3:30. I ran out of material, and had to go to the lumber yard and buy more. While I waited for more boards to be delivered, I adjusted the parking brakes on the roadster. With the trim finished, I turned my attention to replacing the siding I had removed from the north wall of the house when I dismantled the old roof. By quitting time I had most of that done, with just a couple of small pieces left to do. That will be my first chore tomorrow, then I'll be ready to start putting on roofing.

Tuesday, May 19, 2015

I thought maybe I'd start putting on roofing today, but it was not to be. I realized that first I had to replace some siding next to the roof, so I worked on that. Then I had to go buy flashing and roof cement, and while I was at it I drove to Winfield for a couple of jars of 김치. Got back to work on the siding, but had to go back to town for a dental appointment. When I got home at 2:45 I checked the hourly forecast and found a 100% chance of rain at three. I busied myself putting away my tools and getting the tarps in place, and a few minutes after three the rain arrived. My only work on the porch after that was taking a picture of the finished part inside. It shows the new roof and wiring, the relaid stones to the west (left) of the door, and the inside light I installed so I won't have to fumble with my key in the dark. I spent the rest of the afternoon working on the roadster, adjusting the rear brakes, cleaning the oil screen, and changing the oil.

Wednesday, May 20, 2015

I should have taken advantage of the break in the weather by working on the roof today, but I just didn't feel like it. There was no rain, but it stayed coudy, wet, and cold all day. Here we are approaching the last week of May and I had a fire in the kitchen stove tonight. I spent the day on indoor jobs. I put new oil in the roadster, adjusted the transmission brake, cleaned out the excess grease that had leaked into one of the rear brake drums, used some glue putting back in a steering wheel screw that had fallen out, oiled all the places that need oiling, and made a short video on replacing the transmission cover. I spent some time on tire pumps too. The one I thought was my best turned out to be missing a part, so I'll have to restore the one I thought was second best.

Thursday, May 21, 2015

Back to work on the roof today, I put on the metal edge, the first flashing, and a layer of 30# felt. It took a lot longer to do it than to tell it. I was hoping to get started on shingles too, but time ran out. I quit about 3:30 because I had to go to town for groceries. By the time I got home it was 4:30 and I put away my tools and got the tarps in place to keep the rain off my work area. The ten day forecast predicts several rainy days, but I'm hoping for enough breaks in the weather to let me get the shingles done within the next week. Once that's done I can take down the scaffold that's blocking the back door.

Friday, May 22, 2015

My morning project on this rainy day was replacing annoying old ungrounded outlets. The time I spent doing that will save me time wasted later looking for an adapter whenever I want to use something that has a grounded plug. I haven't added ground wires yet. That will come later. In the afternoon I did laundry and put a comforter back on my bed so I can sleep warm again. I don't think the temperature ever got much over 50º today. I didn't expect to use any more firewood until next winter, but this evening I had fires in the kitchen stove and the living room fireplace. It's amazing to still be doing that three weeks into May.

|

Saturday,

May 23, 2015 On another wet day I worked indoors again. I spent a lot of time in the shop working on a Ford tire pump. It was missing a check valve, so I went to the bike shop and got a ball bearing that would fit into the hole where the valve should be. I made a new leather for the pump and installed it, put the ball into its place, screwed on the brass outlet fitting, and tried it out. Each downstroke blew the ball up against the outlet fitting and sealed it so no air could get out. Obviously something else was needed. I made a little spacer coil from a bit of wire to keep the ball from reaching the bottom of the outlet. That worked, but only for a low pressure effort like blowing up an inner tube. The ball isn't quite big enough to fully close the seat, so when I hooked up the hose to an actual tire the air from the tire blew back past the ball. So I need to come up with a better check valve. |

|

Sunday, May 24, 2015

More rain. The gauge had 3.75" in it this morning. There's no flooding yet, but the ground is pretty well saturated. The forecast predicts an 80% chance of no rain for the next three days, so maybe I can get some outside work done before the next dose of moisture hits us. Today I spent a sizable chunk of the morning at the computer, cleaning off some of the items that had accumulated on my desktop. I filed or trashed a lot of stuff but I still have more to do. In the afternoon I worked on the roadster, changing a wheel. The left rear wheel had a worn hub and keyway, so I decided it should go. I had two other wheels. The best one turned out to have a leaking tire, so I went with the second best. I'll put a new tube in that leaker and use the best wheel, but that will wait until I can lay it out in the sun to soften up the rubber. Warm tires are easier to work with.

Monday, May 25, 2015

As Bushytail Squirrel said when Santa brought him a sackful of nuts, "Oh, I am so happy!" I took advantage of a break in the weather and started putting shingles on the back porch roof. By 3:30 I had the east half finished, and had the tools put away and the tarps back in place about four. The half I did today was the more difficult part because some of it is under the overhang of the living room roof, with little space to work. With another dry day in the forecast for tomorrow, I should have no trouble getting the other half done.

Tuesday, May 26, 2015 Almost done. I would have finished the shingles today, but about four in the afternoon ominous thunder to the north and ominous thunder to the south and dark clouds overhead told me it was time to quit for the day. With tools put away and tarps back in place one more time, I retreated to my shop and cut the shingles that will finish the job tomorrow. With that done the scaffold blocking the back door will come down and I'll finish the new window frame and reinstall the window. And with that done, it will be past time to break from working on the house and get some yard work done. |

|

|

|

Wednesday, May 27, 2015

Job One: Cut, sand, and stain two filler boards for the new window frame. Done by 10:30. Job Two: Finish shingling the porch roof. Done by 11:30. Job Three: Take down the scaffold blocking the back door. I was going to dismantle it, but then I thought of squirrels in the attic over my shop. I need to add some steel siding at the top of the wall to close the gaps where they've been getting in. So I moved the scaffold over next to the shop building. Noon break to check email, delete spam, and check forums. Job Four: Clean up a spot in the east end of the shop and move in a set of shelves for nail storage. Job Five: Buy apples and celery. Job Six: Install filler boards. Job Seven: Stain new trim. All that remains to do on this project is reinstalling the window and cleaning up the construction mess.

Thursday, May 28, 2015

The old saying was in full effect today: Everything takes longer than you think it will. Reinstalling the back porch window meant cleaning mortar droppings off the frame, restaining, caulking all the places around the frame that needed caulking, cleaning up the window, and putting it back up. That job was interrupted by the falling branch. I was afraid it had wrecked a good ladder, but the damage was only a small dent. Dragging the branch away and cutting it up took some time, and trying to get my balky truck started took more, so the window took all day. Now that it's back in, about all that remains on the back porch project is cleaning up the construction mess.

Friday, May 29, 2015

This was my day to make a shipping crate to send some rims and hubs off to the Amish wheelwright in Ohio for some new wheels. The forecast showed a 0% chance of rain, but a sprinkle stopped that job and I moved inside and finished taking down storm windows and putting up screens. Usually that's done long before late May, but with this year's cool spring I haven't bothered with it until this week. I did some cleaning up in the new back porch, then when the rain was over I went back to my crate building. In the afternoon I went to town for groceries, bought a sheet of wafer board to finish the crate, and gassed up the Suburban for a trip to Okieland tomorrow. I'll be off to an auction in Cleveland, so I'm taking the gas hog in case I have to haul home something large.

Saturday, May 30, 2015

My day in Cleveland resulted in a few bargains. Most of the stuff on sale was postwar vehicles and parts in pretty rough shape, with a little bit of Model A and Model T mixed in. As usual, there were several things other people wanted more than I did, but I did come home with four items. My haul consisted of a Hayes felloe for $1, a steering column for $2, a rear axle for $2.50, and engine #8305980 (8-31-23) for $10. It happens that the engine was made the same day as the one in my 1924 Model TT project. The two of them were among the 6942 Model T engines made that day.

Sunday, May 31, 2015

The wet month ended dry. I spent the last day of May in the yard. I was going to get the truck running, but the battery was down. So I put a charger on it while I did yard work. I pulled weeds around the house, but there are more remaining to do. I brought out the tractor and mowed. I got a lot of the mowing done, but the tractor was acting like it was having fuel starvation and I stopped to work on that. When I cleaned out the glass bowl filter I found that the nut you tighten to hold the bowl in place was worn out, so I had to repair that. Then I found that the bowl gasket was falling apart, so I had to make a new gasket. By the time I finished working on the tractor it was quitting time, so I'll have more mowing to do tomorrow.

HOME

BLOG LIST

APRIL 2015

JUNE 2015