HOME

BLOG

LIST

DECEMBER,

2013

FEBRUARY

2014

Wednesday, January 1,

2014

I kicked off the new year

by adding a new

website page

about one of my linguistic pet peeves.

I observed the monthly ritual of reading the water meter and writing a

check to pay the bill. As it does most months, that amounted to $17.

When I use a lot of water it's $19. Hearing from people in town what

they pay, this is one more thing that makes me glad to be outside the

city limits and in a rural water district. When I went to town for milk

this afternoon, I also bought a fifty foot network cable. I've found

that the wi-fi signal from my router in the house doesn't reach out to

my workshop. So I've decided to try moving the router from the living

room up to the attic to see if the signal will reach both the living

room and the shop from there. I'm hoping that the signal will get out

past the wood wall upstairs better than the concrete and stone walls

downstairs. This afternoon I drilled a hole in the northwest corner of

the living room wall near the ceiling. That hole opens into the

northeast corner of the upstairs bedroom just above the floor. I

managed to thread the cable through the hole before quitting time.

Tomorrow I'll move the router upstairs, hook it up, and see if the

signal reaches both places. I had to quit about four because I had

baking to do. I made cornbread to have with the traditional New Year's

Day meal of black eyed peas. I need to make cornbread more often. It's

good stuff.

Thursday, January 2, 2014

A cool 7º F greeted me when I looked out the kitchen window this

morning. I did a little more organizing and cleaning in the shop

today, but I spent more time on a couple of other things. The

first was my attempt to get a wi-fi signal in the shop. I moved

the router from the living room up into the attic, over the northwest

room nearest the shop. The good news was that it still sent a good

signal to the living room. The bad news was that out in the shop my

browser still showed a "Server not found" notice. Thinking about the

physical layout of the place, it occurred to me that the obstacle might

be the east end of the shop building, made of concrete blocks. So if the signal wasn't

getting into the ground floor of the shop, maybe the upstairs,

made of metal siding over a wood frame, would be a different story.

Yes, it was. I was delighted to find that when I took the computer up

there I was able to go online with no trouble. So my next project was

making a computer table to go upstairs over the shop. With that

question settled, I

went back to indexing photos. By the time I quit this evening, I had

finished all the Mays from 2007 through 2013. I'm closing in on having

half the indexing project done.

|

|

Friday, January 3, 2013

A warmer day, above freezing, but with

enough wind to make it feel a lot colder. I continued indexing photos.

I made it through June of 2008. That leaves June 2009, 2010, 2011,

2012, and 2013 until I'm about half done with the indexing. I'll do

some more tomorrow, but I still need to do more shop organizing too so

I can get to work on that roadster rear axle. Gotta get that car ready

to drive when touring season gets here.

Saturday, January 4, 2014

Curses! Opportunity lost. A sunny day above 40º would have been good

for cutting firewood, but my saw died. It's in the repair shop waiting

for parts. So instead of woodcutting I did more picture indexing and a little more shop organizing. This was the last day for outside work

until Tuesday. We're supposed to

go back in the icebox for the next three days.

|

Sunday, January 5, 2014

This morning I awoke to about two or three inches of snow on

the ground and an outside temperature of 11º F. Certainly it was no day

for outside activities. I played online, indexed more pictures, and

made some progress in workshop organizing. It wasn't a day of major

accomplishment, but I got a little done. When I went in to get dinner,

the temperature in the kitchen was 32º F. I lit a fire in the stove and

set a fan on the chair behind the stove to help circulate the warm air

around the room, and in half an hour the temperature had risen to

almost 70º F. Miss kitty seemed to appreciate that stove. In the

evening I returned to indexing pictures. I got through June of

2011. Outside it's chilly. A little after 10 PM the outside

thermometer claimed it was 6º. We might get down around zero by

morning. Today's high was 20º just after midnight. I don't think

we ever got much above 11º in the afternoon. I'll enjoy

those electric blankets tonight.

Monday, January 6, 2014

This morning's 0º F was the coldest we've had here so far. Here in the

shop it's 60º upstairs where I have the computer, and my toes are cold,

but at least my fingers aren't numb. I did more indexing of pictures,

and now have the first six months

of every year since 2007 done. That's about half of all the pictures I

have to do. At that point I quit indexing for the day and went back to

shop organizing. I managed to clear off the top of the old heater I've

been using with a board across the top for a table. It's been sitting

behind the roadster. With that heater out of the way I'll soon able to

pull the rear axle out of the roadster and go to work on it. I hope

I'll have that car ready to drive when nice weather arrives. are cold,

but at least my fingers aren't numb. I did more indexing of pictures,

and now have the first six months

of every year since 2007 done. That's about half of all the pictures I

have to do. At that point I quit indexing for the day and went back to

shop organizing. I managed to clear off the top of the old heater I've

been using with a board across the top for a table. It's been sitting

behind the roadster. With that heater out of the way I'll soon able to

pull the rear axle out of the roadster and go to work on it. I hope

I'll have that car ready to drive when nice weather arrives.

Tuesday, January 7, 2014

As the polar vortex began to dissipate and the outdoors warmed up into

the thirties, I did more organizing in the shop and did more picture

indexing. I've decided that since the wi-fi signal from the house

reaches the upstairs of my shop and that's where I've moved my

computer, that's where I'll have my office. So

today I set up the printer and the scanner next to the computer.

Eventually I'll get the filing cabinets out of the living room and put

them up there too.

|

|

Wednesday,

January 8, 2014

I never went off the place today. My main project was making a jack

attachment. It's bad practice to raise the rear end of a Model T by

placing a jack under the center, so I came up with a way for a single

jack to lift in two places. With that tool finished, I used it to

put the rear of the roadster up on jack stands. With a length of square

tubing under the frame and between the muffler and the spring, the rear

axle is easily removed. Just disconnect the brake rods and

shackles, remove four bolts from the front of the drive shaft

housing, and the whole thing pulls out toward the back. Soon I'll

have that rear axle out and can open it up to see what's inside. I

suspect I'll find some of the old babbitt

thrust washers that need to be replaced. While I have the rear axle

out I'll install the proper 1915-style rear spring, shackles, drive

shaft tube, and pinion spool.

|

|

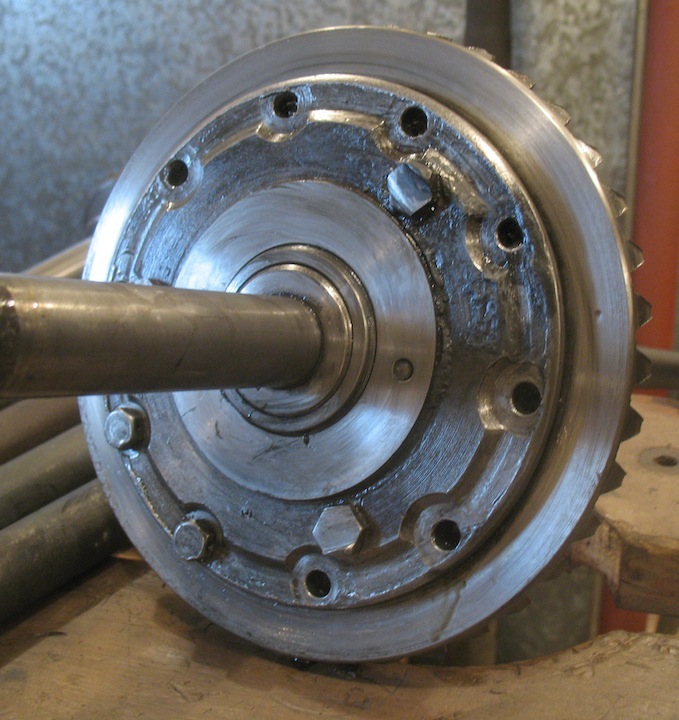

Thursday, January 9, 2014

This morning I indexed all my

July 2011 pictures. That leaves July for 2012 and 2013 to do, then I

can move on to August. This afternoon I pulled the rear axle out of the

roadster, removed the bolts holding the two halves of the housing

together, and left the thing sitting over a pan for the oil to drain

out. It took a bit longer than it needed to because I made a video of

every step. As I do the rebuilding job I'll show each step for the

benefit of those who have never rebuilt a rear axle. Tomorrow I'll open

the thing up all the way and see what's inside.

Friday, January 10, 2014

The best laid plans... I never did get that rear end opened to see

what's inside. I removed the perches and brake parts and some other

parts, then came cleaning. I intended to wash the parts in old paint

thinner in a pail. When I went looking for a putty knife to clean out

the pail I ran aground on the shoals of missing tools. It seems no

matter how many putty knives I buy, I can never find one when I need

it. By the time I went to town for one, and to the courthouse to pay

the tax on my trailer, and the lumberyard for blasting sand, and a few

other stops, that was my afternoon. Maybe I'll get that rear axle

opened up tomorrow.

|

Saturday, January 11, 2014

Today I dug into that rear

axle and was delighted to find that most of

the parts I checked were OK. The thrust washers are bronze, not the

notorious babbitt type. Three of the four axle bearings are good to

excellent. The fourth has too much wear, so I'll replace it. I guess

whoever rebuilt this axle couldn't find a better one. If all the other

parts in this axle check out as well as the ones I've measured so far,

I'll be a happy camper.

Sunday, January 12, 2014

Today was perfect for sandblasting, with mild temperatures and enough wind to carry away the dust. Unfortunately

I didn't have any parts ready to blast. The forecast is for more good

weather in the coming week, so I'll do my blasting then. I drove up to

Winfield and over to Oxford to check out the auctions, and found

nothing to keep me at either one, so I came home and did more rear axle

dismantling. I found that enough water had found its way into the

housings to cause some rust, so I'll be sandblasting for sure. This

rear axle has been rebuilt before. It was recently enough to have

neoprene seals and blue goo inside, but far enough back to have spiral

grooves in the thrust washers. The current thrust washers have straight

grooves.

|

Monday,

January 13, 2014

With time out for a trip to town

to replace a burned out work light bulb and pay some bills, I continued

work on the rear axle. I got the housings cleaned out and ready for

blasting. The next question is when to do it. The forecast for tomorrow

is chilly and windy, but I may try it so I can get the things painted

and drying while I work on other parts.

Tuesday, January 14, 2014

Never went off the place today.

My first job was making a drive shaft tube support that bolts to my

work table. That's part of rear axle rebuilding. Making the support

used up most of my morning, proving once again that everything takes

longer than you think it will. About one I went out and set up the

sandblasting equipment and went to work on the right half of the axle

housing. It was a pretty good day for blasting. Not too cold (above

45º) and with enough wind to carry away the dust so I didn't have to

wear the hood. After awhile the wind died down and I had to use the

hood. That slowed me down just because it's harder to see what I'm

doing when I have it on. I kept at it and had the piece finished and

the equipment put away by four. This evening I painted that half, and

with any luck tomorrow I'll get the left half blasted and

painted.

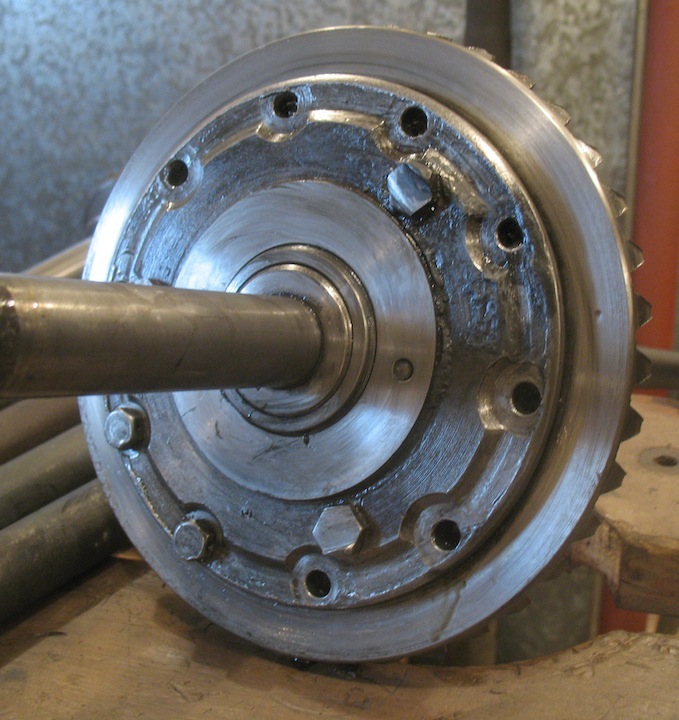

Wednesday, January 15, 2014

The great taking-apart continued this morning. The biggest part of that

was the drive shaft, especially getting the pinion gear off the end. I

tried three different three-jaw pullers, and all of them proved to be

feckless junk. So I went online and found a very simple method from

Stan Howe, a Model T guy who knows his stuff and has lots of good

ideas. I had the gear off in a couple of minutes.

In the afternoon I turned again to sandblasting the left half of the

axle housing. There was no wind today to carry away the dust, so I had

to wear the hood the whole time. The cold air blowing into the hood

turned my nose into a snot fountain, so it was slower going than

yesterday's session. I got the ends , the hardest part, almost

finished. The next session should finish up the whole

thing. After I get that left half blasted and painted so it can

be drying, I'll get started on the nuts and bolts and other small

parts.

|

Ready for rear axle rebuilding.

|

Blasted and ready to paint.

|

Thursday, January 16, 2014

Mission accomplished. After a morning session of more rear axle

dismantling, I had the sandblasting equipment set up by noon and went

to work on that left housing. I had it done by 2:20 and the equipment

put away by 2:40. I ended up with a trip to town to pick up the

new chain saw I ordered Monday. I've been skipping evening fires

because I was almost out of wood, but tonight I fired up the stove and soon

had the 45º kitchen up above 70º.

Tomorrow and over the weekend I'll put that new saw to work and build

up my wood supply.

Friday, January 17, 2014

A bit of housekeeping this morning. Since I've decided on having an

office upstairs over my workshop, I got a little bookcase out of the

house and put it up there. I boxed up the romance novels that occupied

the shelves and replaced them with my Model T and tractor books.

In the afternoon I went grocery shopping, then piddled around on minor

inside chores. I did make a scouting trip down to the woodlot to

locate some dead trees to cut up, and I put oil and fuel in the new

chain saw, so I'm ready to make firewood tomorrow.

|

Saturday, January 18, 2014

Two main activities today. In the morning I did more rear

axle dismantling, taking things apart, cleaning the pieces, and

checking their condition. Some of the parts looked good until I

measured them. A few items are a little too worn to suit me. They'd be

OK if I never drove the car more than a few miles from home, but if I

go on longer trips I'll want things in better shape. I'll open up some

of the spare axles I've picked up at auctions and see if I find

anything better in them. In the afternoon I took the new chain saw down

the lane and finished cutting up the fallen tree that was blocking the

road. I also uncovered some small trees I cut down a couple of years

ago and laid along the fence to dry out. They're dry. Today I got them

out of the dead grass that was covering them. Tomorrow they'll go into

my firewood supply.

|

|

Sunday, January 19, 2014

Sixty days til spring! But this weekend seems like an early one. After

a morning of indexing more photos, I went out to make more firewood. I

finished cutting up those former small trees along the lane, and while

I was at it I took a little walk down to the woodlot to scout out some

of the dead trees that have fallen across one of the roads. There's a

big old hedge tree that still has enough roots in the ground to be

alive. I'll cut enough of it to open the road so I can get to the dead

stuff beyond it, but most of it can wait until this year's wood heating

season is over. Then I'll cut it all up for next winter. I boxed up the

smaller pieces from today's cutting and set them in the garage, and

tomorrow I'll bring up the larger pieces. Some are big enough to go to

the splitter, and some will go directly into the stack in the

garage.

Monday, January 20, 2014

An unexpected job took up a big part of the day. Bob Bergstadt of Bob's

Antique Auto Parts announced on the Model T forum that he was having a

free shipping day today, so I spent a few hours figuring out what I

need for my rear axle project, making a list, and ordering the parts.

My cousin Wally stopped by with some wood scraps to donate to my

firewood supply, and we chewed the fat for awhile. Then a trip to town

for a jug of rust remover for the shop and some celery for me

finished up the day. The best part of the day was a reduction in the

leaking that's had me in old folks' diapers since my surgery in

September. Some days I've had to use a new absorbent pad every two or

three hours, but yesterday and today I've been going from seven to

twelve hours between changes. My dentist told me it took his dad a year

to quit leaking after his surgery, so I guess I'll be lucky if I can do

it in only six months. Using the diapers and pads isn't a major

tragedy, but its an inconvenience I'll be glad to do without.

|

Tuesday,

January 21, 2014

Never went off the place today. I

worked on the rear axle project,

cleaning and checking parts. Having found that a few pieces are too

worn to suit me, I brought in one of the rear axles that have been

sitting on my trailer since I bought them at an auction in September,

and started taking it apart to see if it has some better parts in

it. The inner axle bearings looked pretty good. In fact one

of them was gorgeous, with smooth surfaces and a nice, tight

cage. But measuring the rollers showed .0045" to .007"

wear, which is well over the recommended .002" limit. Oh, well.

Bearings weren't the main thing I was after. What I'm looking for

is a better spider than the one that was in the roadster. I still have

to clean and open up this differential

to see if it has a good one.

|

|

Wednesday, January 22, 2014

Today I finished dismantling that rear axle in search of parts. I

didn't find anything better than what I already had, so I brought in

the next one off the trailer and started taking it apart. A little

after four I quit to fetch firewood. The forecast claims real winter

will return tomorrow, with a single-digit low and a high of about 20º.

So I went down to the lane where I cut up that wood last weekend, and

brought three boxes of it up to the house. I'm spending most of my time

in the shop these days, just going to the house at meal time. In the

couple of hours I'm there in the evening the wood stove makes the

kitchen very pleasant. I expect those three boxes of wood to last at

least until Sunday.

Thursday, January 23, 2014

Rear axle disassembly continued to be the project of the day. I

spent all day on it, finishing up the second one and bringing in the

third one off the trailer. Cleaning the old oil, grease, and dirt

out of these things is slow going, but that's OK. All that grease and

oil prevent rust. So far I've found a few good, usable

parts, but not the one I really want. Both spiders have been about the

same as the one I took out of the roadster. Not terrible, but with a

little more wear than I'd like. Maybe the next one will be better. This

evening I did more picture indexing. If I keep coming back to it a

little at a time, eventually I'll have it all done. The part I've

done so far has already come in handy for finding some pictures I

wanted.

Friday, January 24, 2014

And still more rear axle dismantlement filled my morning. It doesn't

take much to tell about the day. Doing laundry and buying groceries

used up most of the afternoon, and bringing in wood for the evening

fires used up the rest. I did laundry on Friday instead of Saturday

this time because tomorrow I'm off to Hutchinson for the mid-winter

model T seminar.

Saturday, January 25, 2014

Before daylight I was on the road to Hutchinson for the annual

Mid-winter Model T Seminar. As always, I learned some things I didn't

know before.

Sunday,

January 26, 2014

Wheee! This was hump day on the weather roller coaster. We climbed up

to a high point of 64º F this afternoon, then the wind shifted around

to the north and we began the plunge down to a predicted overnight low

in the teens. I took advantage of the warm weather and

comfortable temperatures in the barn to wire brush nuts and bolts.

Specifically, the ones that hold the halves of a rear axle housing

together. Each housing takes seven of each. The ones I've been

salvaging aren't all usable, but most are. I ended up with enough for

two rear axles with a few extras left over. Reclaiming these things

takes several steps. First, wire brush away all the rust on each piece.

Then grind off any burrs and protrusions. Then run a tap through all

the nuts, and run all the bolts through a die, to chase the threads.

Next will be painting. That includes making wire hangers to hold all

the pieces during painting and drying. The wire part of that will take

a lot more time than the paint part.

Monday, January 27, 2014

Cats come and cats go. Almost never do I find any remains. They're

here, then they're gone. I figure that when I don't see them anymore

they've been dinner for a coyote, or an owl, or some other wild critter.

So when Miss Kitty didn't show up at feeding time yesterday and today I

wondered if she had become some wild varmint's snack. But this evening

when I left the house to come to the shop, there she was. She's six

years old now, and a good and experienced hunter, so I suppose she's

been off on a hunting expedition for a couple of days.

|

|

Tuesday, January 28, 2014

This was the day to pay a few bills and do some shopping for house and

shop supplies, and replace a thermometer. I had one hanging on a tree

outside my shop, but the north wind that brought in the current cold

spell blew it to the ground and I had to put it back. Today's work in

the shop was opening up another rear end to see if it has any usable

parts. I haven't done all the cleaning and taking-apart yet, but so far

this one looks pretty bad. I'll be surprised if I find two or three

usable parts in it.

Wednesday, January 29, 2014

Today's main task was more indexing of photos. I kept at it until late

in the evening and finished everything up through August for the past

six years. That leaves September through December yet to do, so I'm

two-thirds done.

Thursday, January 30, 2014

A lovely warm day in the high forties was my time to get out and lay in

some firewood. I split the pile that was waiting by the splitter,

brought up the stuff I cut down in the lane a couple of weeks ago and

split that, brought some into the house, and stacked the rest in the

garage. According to the forecast this was the last warm day for

awhile. A lot of the highs for the next ten days are supposed to be

freezing or below. I think the wood I laid in today will cover it

though.

|

Friday, January 31, 2014

With fifty days til spring we're back to normal winter weather, with

highs in the thirties and forties and lows in the teens and twenties. I

did get some work done in the shop today, but not as much as I should

have. I've discovered a Facebook page devoted to local history, so I've

been wasting too much time on that. It's interesting, but I have a lot

of other stuff I need to get done. At least I did mostly finish

dismantling the rear axle I started a couple of days ago. It's the

worst I've seen so far. Apparently after the thrust washers

disintegrated the driver ignored the noise and just kept driving. The

thing was packed with a mixture of grease, dirt, and ground up parts.

When I finally got it cleaned out I found that seven of the ten ring

gear bolts were gone, and the heads of the differential case bolts were

half ground away. The ring gear looks a lot better than I would have

expected from the rest of it, and the spider had surprisingly little

wear. I still have a little more dismantling and parts cleaning to do

on this axle, then I'll start on the next. A lot of the parts I'm

finding are worn out, but I am finding some good pieces too.

|

|

are cold,

but at least my fingers aren't numb. I did more indexing of pictures,

and now have the first six

are cold,

but at least my fingers aren't numb. I did more indexing of pictures,

and now have the first six